What Does Roar Solutions Do?

( Zone 0, 1, or 2). This variant will certainly additionally affect the resourcing demands for work preparation. Once Lots are defined, you can develop sampling plans based on the sample size of each Great deal, which refers to the number of arbitrary devices things to be checked. To figure out the needed example size, 2 elements need to be examined: the size of the Lot and the classification of examination, which shows the degree of initiative that need to be applied( decreased, normal, or increased )to the assessment of the Great deal. By incorporating the classification of inspection with the Whole lot size, you can then develop the suitable rejection standards for an example, meaning the allowable number of faulty products located within that example. For more details on this process, please describe the Power Institute Guidelines. The IEC 60079 basic suggests that the maximum interval in between inspections need to not go beyond three years. EEHA assessments will also be performed outside of RBI projects as component of arranged maintenance and tools overhauls or repair services. These inspections can be credited towards the RBI example dimensions within the affected Lots. EEHA examinations are carried out to determine mistakes in electric devices. A heavy scoring system is crucial, as a single tool may have several faults, each with varying degrees of ignition danger. If the mixed score of both evaluations is less than two times the mistake rating, the Whole lot is regarded acceptable. If the Whole lot is still considered undesirable, it should go through a complete evaluation or justification, which might set off more stringent evaluation methods. Accepted Great deal: The reasons for any kind of mistakes are identified. If an usual failing mode is discovered, added tools may need maintenance. Mistakes are categorized by seriousness( Security, Honesty, Home cleaning ), ensuring that immediate issues are examined and dealt with without delay to reduce any type of impact on security or procedures. The EEHA data source should track and videotape the lifecycle of mistakes along with the restorative activities taken. Implementing a robust Risk-Based Inspection( RBI )strategy is essential for making certain conformity and safety and security in handling Electrical Equipment in Hazardous Locations( EEHA). Automated Fault Rating and Lifecycle Management: Effortlessly take care of faults and track their lifecycle to improve inspection precision. The intro of this support for risk-based inspection further reinforces Inspectivity's position as a best-in-class remedy for regulative conformity, in addition to for any type of asset-centric evaluation usage instance. If you have an interest in learning extra, we welcome you to ask for a demonstration and uncover exactly how our remedy can change your EEHA management processes.

With over one decade of mixed Ex experience (IECEx/ATEX, EEHA), Saipex began to advertise the importance of skills of all workers associated with the Hazardous Area field in 2019. In 2021, our partnership with IndEx and Tech Ability International (TSI) marked a turning point in the Saipex road to continue Ex-spouse improvement.

Not known Facts About Roar Solutions

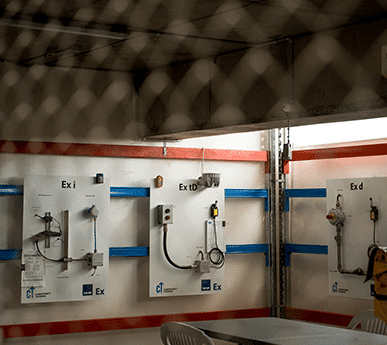

In terms of eruptive risk, a hazardous area is an environment in which an eruptive atmosphere exists (or might be anticipated to be existing) in quantities that require unique safety measures for the building and construction, installation and usage of equipment. In this short article we discover the challenges faced in the workplace, the danger control measures, and the required competencies to work securely.

It issues of contemporary life that we produce, store or deal with a series of gases or fluids that are deemed combustible, and a series of dirts that are deemed combustible. Roar Solutions. These substances can, in certain conditions, form eruptive ambiences and these can have significant and terrible effects. A lot of us are familiar with the fire triangular get rid of any type of one of the 3 elements and the fire can not happen, yet what does this mean in the context of dangerous locations? When breaking this down right into its simplest terms it is basically: a combination of a certain quantity of launch or leakage of a certain substance or product, blending with ambient oxygen, and the visibility of a resource of ignition.

This is then validated with assessment and testing and is protected throughout the life of the setup by employing the right maintenance methods, supplemented by periodic inspection. When all these steps are taken, they ought to also be recorded. The confirmation dossier includes details such as the unsafe area classification drawing, manufacturers' documentation, equipment certification, layout illustrations and calculations, evaluation documents, and records of an individual's competency and proceeding professional growth (CPD), such as by means of ECA's eCOMS software application.

The Best Strategy To Use For Roar Solutions

It is important that trainees comprehend and have a thorough expertise regarding what precisely comprises a harmful location. The pupil must likewise recognize why training is very important before trying to tackle work or defining equipment right into a dangerous location. These areas are also recognized as classified areas and are defined as locations which have a high likelihood of an explosion because of the feasible presence of combustible gases, vapors, dusts and so on.

Industries that include hazardous locations are now demanding that electric workers that are defining or operating in these locations must More Bonuses have a hazardous location credentials that deems them skilled. Jobs in these sectors are extremely rewarding so you need to be prepared. To satisfy this demand for the industry, across the country identified training in Certification IV in Hazardous area Electric and EEHA training on the growth of experienced professionals.

The Ultimate Guide To Roar Solutions

Tech Abilities Australia is a Registered Training Company giving you with one of the most inexpensive and quickest method getting your certification - hazardous area electrical course. Our instructors are sector qualified and have numerous years of process experience. Our training courses have helped numerous people from business managers to daily workers in getting a solid hang on this not so challenging however high risk training

The training likewise consists of recognizing the hazardous locations, resources of surge and the residential properties of harmful materials in addition to the duties and functions of all events, guidelines, systems, criteria and practice codes connected to dangerous locations. We offer instrumentation and unsafe area services that remain in compliance to latest AS/NZS and international industry requirements.

Comments on “The Definitive Guide to Roar Solutions”